Machine tools retrofitting

We have more than 50 years of accumulated experience rebuilding used machine tools.

The reconstruct of used metalworking machinery process requires wide expertise in mechanical, hydraulic, lubrication, pneumatic, electrical, control, and coolant systems, as well as knowledge of the process the machine performs.

Maquinaria Colás has the experience, knowledge and the highly skilled team to complete successfully the process of rebuilding used machine tools

The rebuilding process will require each of machines to be disassembled, cleaned, inspected, and repaired or replaced as required.

Retrofitting examples

Bed Type Milling Machine Zayer ZF 2000

CNC HEIDENHAIN TNC-426. Table Surface:2.000 X 1.000 mm. Travels (X/Y/Z): 1.725 /1.200/1.000 mm. Automatic Head:2×180º / Manual Head Hydraulic Tool Clamper Portable

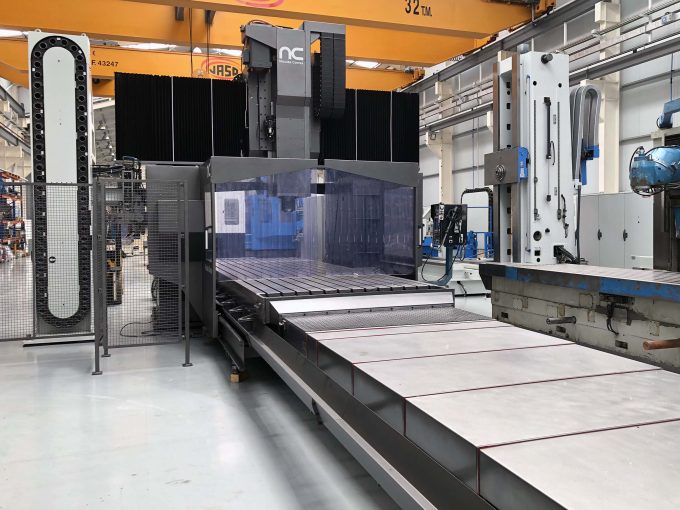

Correa FP40/60 Bridge Type Milling Machine

Reconstructed Portal Type Milling Machine CNC: Heidenhain TNC 530 Table Surface: 6.000 X 2.000 mm Travels (X/Y/Z): 6.000 /3.000/ 1.000 mm Distance between centers 2.520 mm Direct Output

Bridge Type Milling Machine Zayer FP 10000

New in 2006. Reconstructed in 2015. CNC Heidenhain TNC 530. Table Surface: 10.000 X 3.000 mm. Travels (X/Y/Z): 10.000/4.200/1.100 mm. Distance Between Columns: 3.500 mm. 30 Tool ATC. 3

Correa CF 25/35

New in 2.002 with CNC HEIDENHAIN TNC-530 Table surface:3.800 x 1.000 mm. Travels (X/Y/Z): 3.500/1.000/1.000 mm. Automatic head UAD 0.1º/ 0.1º Internal coolant 20 bar ATC 30

Rebuilt Bridge Type Milling Machine Nicolas Correa FP 40/40

Bridge type milling machine with CNC HEIDENHAIN TNC-530 New in/reconstructed in :2003 /2021 Table surface :4.000 X 1500 mm Travels (X/Y/Z) :4.000/2.500/800 mm Distance between columns

USED CNC LATHE LEALDE TCN 12

Maximum Diameter over Bed: 710 mm. Maximum Diameter Carriage: 505 mm. Slant bed; 60º Turret: 12 Stations Hydraulic Chuck: Ø 500 INCLUDED Chip Conveyor: INCLUDED Control: FANUC 0 New in

Used Zayer KP-5000 5 Axis Bridge Type Milling Machine

Used Zayer KP-5000 5 Axis Bridge Type Milling Machine. CNC Heidenhain TNC 530. Autoindex Head 360.000 positions. Reconstructed in 2017. Immediate Delivery. Can be Inspected under power.

ZAYER 30 KFU-3000 AR Bed Type Milling Machine

New in 2003/ Reconstructed 2019 CNC HEIDENHAIN TNC 530 Travels (X/Y/Z):2.700/1.250/1.500 mm. Auto Index Head 45º 0.001º/0.001º Internal Coolant 20 BAR ATC 30 Tools Double Chip

A complete rebuild process takes place in a series of steps, depending on the machine and its complexity:

1) Disassembly, cleaning, and inspection.

2) Engineering of software, electrical, mechanical, and fluid systems.

3) Ordering of the required parts.

4) Paint when necessary.

5) Machine rebuilding.

6) Startup and debug.

7) Mechanical recertification.

8) Test cycling and initial test cutting.

9) Runoff and final testing.

After the process the used machine tools rebuilt by Maquinaria Colas have the sale quality as they had when they were originally bough.

Before buying a new machine, why don’t you consider to buy a rebuilt metalworking machine at Maquinaria Colás? Make the second use machine tools your first option and you will save up to 50% compared with new.

Have a look to our used machine tools stocklist on this site or contact us to set up and visit to see the quality of our rebuilt used metalworking machinery